September 30, 2025

Recent Articles

The Art of Precision: Waterjet Cutting Technology Advantages

Waterjet cutting is transforming modern stone landscaping with unmatched precision, versatility, and sustainability. From intricate designs to reduced material waste, this technology empowers architects, landscapers, and developers to bring creative visions to life without compromise.

5 Reasons Waterjet Cutting Is Changing the Game

Discover 5 powerful reasons why waterjet cutting is transforming stone design in Australia. From unmatched precision to eco-friendly efficiency, learn how this cutting-edge technology is shaping the future of landscaping and architecture.

The Future of Natural Stone Landscaping in Australia: Key Trends You Need to Know in 2025

Explore the top natural stone landscaping trends shaping Australia in 2025. From sustainable sourcing and minimalist design to earthy tones and waterjet precision, this guide covers the latest materials and innovations.

Why Waterjet Cutting is the Smarter Choice for Stone Design

As architecture continues to evolve, the pursuit of innovation, precision, and sustainability drives the adoption of advanced technologies. Among them, waterjet cutting stands out as a transformative force, opening new possibilities for architects.

In both Australia’s domestic gardens and commercial landscapes, the demand grows for clean lines, bespoke features, and durable natural materials. Homeowners seek patios and outdoor rooms that look elegant without feeling generic, while developers and municipalities create plazas and public spaces that feel distinct, refined, and timeless.

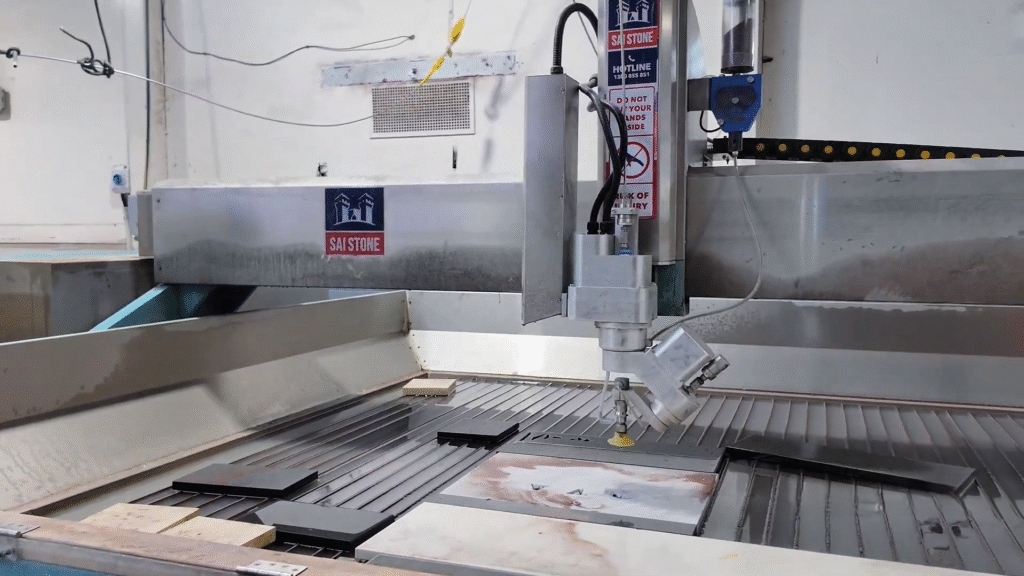

Through the help of waterjet cutting technology, which is quietly transforming how we design with stone, designers and landscapers gain the tools to realize creative visions with precision, speed, and sustainability. In short, for today’s landscaping projects, waterjet cutting proves to be the smarter choice and SAI Stone makes this possible by delivering expertly crafted, high-quality stone products cut with advanced technology.

What is the Water Jet Cutting Machine?

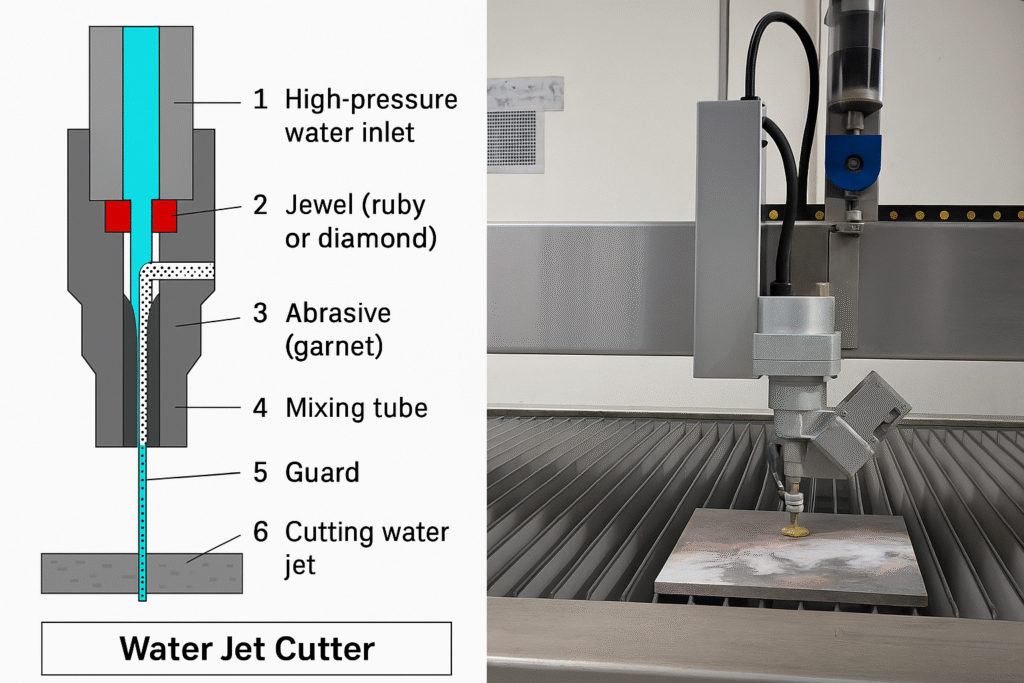

An advanced tool that uses high-pressure water, which is often combined with abrasive material, to cut through a wide variety of materials. This machine can cut without heat, with its ability to deliver precise and clean cuts, preserving the material’s intrinsic properties.

Since waterjet cutting works through a combination of pressure, precision, and automation. A high-pressure pump pressurizes water up to 60,000-90,000 psi, creating the force needed for cutting.

The water stream is then directed through a small nozzle, often mixed with abrasive particles like garnet, which enables the machine to cut through harder materials such as granite or marble.

To achieve accuracy, the process is typically controlled by a CNC (computer numerical control) system, allowing designers to produce intricate, complex, and highly precise cuts with consistency.

What are the Advantages of Water Jet Cutting?

Water jet cutting is a versatile and precise machining method that stands out in the manufacturing and fabrication industry for its numerous benefits. They are preferred method for both domestic and commercial landscaping projects:

Precision and Accuracy

One of the biggest strengths of waterjet cutting is its ability to cut with millimetre-level precision. This high accuracy makes it possible to create detailed shapes and patterns that other cutting methods can’t achieve. With waterjet cutting, you can cut stone to exact sizes, so every piece fits perfectly in place.

In complex landscaping layouts stepping stones, interlocking pavers, custom feature walls, small misalignments would look sloppy. For higher-end commercial projects, clients expect clean joints, tight tolerances, and seamless transitions between materials.

Meanwhile, in residential contexts, precision means fewer adjustments on site, faster installations, and fewer cuts onsite which means less dust, noise, and disruption to neighbours.

Intricate and Customised Designs

Waterjet cutting doesn’t just do straight lines, it lets you realize curves, mosaics, logos, filigree patterns, and virtually any artistic cut you can imagine.

With the help of waterjet cutting technology you can have creative possibilities such as having decorative patterns or medallions in a patio or forecourt. Custom logos or motifs in commercial plazas or corporate landscapes, you can also do wavy or organic edge profiles in garden beds or sitting walls.

By giving designers freedom, waterjet cutting elevates the aesthetic possibilities of stone landscaping. A backyard feature wall can become a custom artwork; a commercial entrance can make a striking first impression.

Reduced Material Waste

Stone is a premium, finite natural material. Traditional cutting often creates significant offcuts, chips, or unusable scraps because of wide saw kerfs, imperfect cuts, or mistakes. However, waterjet cutting produces a minimal kerf (cut width) and thus conserves material.

Its precision allows multiple shapes to be nested closely, maximizing each slab and reducing waste. Making the waterjet cutting technology efficient, making consumers save money on material costs while supporting a more sustainable approach to landscaping by using natural resources responsibly.

Faster Turnaround Times

Time is important, especially when doing landscape projects. Through the help of CNC automation it streamlines production and speeds up delivery of both small-scale and large-scale landscaping projects.

When you automate cutting using CNC and waterjet, you remove much of the manual labor and corrections required in traditional stone-shaping. It saves you time as quicker project delivery means designers, landscapers, and contractors can move from design approval to installation more swiftly.

Additionally, it reduced labor costs with less time spent chiseling, trimming, or correcting onsite. For commercial developers on tight schedules or homeowners wanting fast project completion, this speed is a big competitive advantage.

Versatility Across Stone Types

One reason waterjet cutting is so powerful in landscaping is its compatibility with many stone types like granite, marble, basalt, bluestone, limestone, sandstone, and more. Waterjet cutting’s ability to handle diverse materials is exceptional. This method can efficiently cut through metals, plastics, glass, composites, and stones without using multiple tools.

This versatility also means that designers aren’t forced to compromise their material choice because of fabrication constraints. You can match the stone type to the architectural style, climate conditions, or desired finish. With waterjet technology, it works equally well in small-scale residential jobs and in the large slabs needed for civic and commercial landscapes.

Environmental Friendly

Waterjet cutting technology stands out for its relatively green and safe profile, making it a noteworthy advantage. Since it does not produce hazardous waste and primarily uses water as the cutting medium, it minimizes environmental impact compared to processes that generate dust, fumes, or thermal distortion. Additionally, the water used can be treated and recycled, and because it is a non-toxic natural resource, it can be repurposed for other applications.

Safe and Cleaning Process

Another advantage that waterjet cutting stands out is with its safe and clean process since it doesn’t produce fumes, dust, or other harmful byproducts. Instead, waterjet cutting helps maintain a healthier work environment for operators. Its cold-cutting process also eliminates the risk of burns or fires, which improves overall workplace safety. The clean method not only protects workers but also reduces the need for extensive cleaning and maintenance, making the production process safer and more efficient.

Durability and Quality Finish

Because the cutting process is gentle and free from heat-affected zones, the edges remain smooth, clean, and consistent. That improves both the strength and the aesthetic quality of the stone.

Smooth edges reduce stress concentration points and lower the risk of cracks during installation. The uniform finish gives a professional, high-end look, and well-cut stone ages attractively while requiring less maintenance.

Applications in Landscaping

Waterjet cutting opens up a wide range of applications in both domestic and commercial landscaping. In residential settings, it can be used to create custom garden paths, pool surrounds, decorative walls, and patio flooring that combine elegance with durability. For larger civic or commercial projects, waterjet-cut stone enhances shopping centres, public squares, and corporate landscapes with distinct designs and long-lasting finishes.

Summing Up

Waterjet cutting offers various advantages that make it precise, versatile, and eco-friendly. Its advantages include cutting complex shapes without compromising material integrity, making it an invaluable tool for various industries. With the advantages it provides, it improves results, saves money, adds convenience, and delivers many more benefits of waterjet cutting.

For years past and years to come, waterjet cutting continues to prove itself as the smarter, future-focused choice for stone design. For homeowners, developers, and municipalities alike, it represents not only innovation but also a more sustainable way to use natural stone responsibly.

Water Jet Cutting Services at SAI Stone According to Your Needs

SAI Stone Waterjet Cutting Technology Service stands out for its custom approach to meeting client needs. We offer precision cutting for natural stone, porcelain, and bricks to any shape. This method is ideal for projects that require intricate designs or delicate materials, ensuring high-quality results without thermal damage or material deformation.

Additionally, we deliver bespoke projects, pool coping, and special inlays that you may need for your next project. Our engineers work closely with clients to ensure specifications meet precision. With more than two decades of experience working with industries, we bring expertise and reliability. Moreover, you benefit from a partnership with SAI Stone, as we value precision, adaptability, and sustainability.

So, what are you waiting for? Contact us today to discuss your vision, ask for examples, and let’s cut and build your next project with SAI Stone.

FAQs

1. What is waterjet cutting in stone landscaping?

Waterjet cutting is a technology that uses high-pressure water, often mixed with abrasive material like garnet, to cut natural stone with precision and without heat.

2. Why choose waterjet cutting over traditional stone cutting?

Unlike traditional methods, waterjet cutting creates smooth, accurate edges, reduces material waste, supports intricate designs, and avoids heat damage to stone.

3. Can waterjet cutting handle all types of stone?

Yes. Waterjet cutting works on granite, marble, bluestone, sandstone, limestone, and more. It also cuts other materials like porcelain, bricks, and even metals or glass.

4. Does waterjet cutting damage the stone surface?

No. Because it’s a cold-cutting process, it avoids heat-affected zones, ensuring the stone keeps its strength, durability, and natural beauty.

5. Is waterjet cutting cost-effective for landscaping?

Yes. Although the technology is advanced, its precision reduces wasted slabs, speeds up project timelines, and lowers overall material and labor costs.