September 29, 2025

Recent Articles

The Art of Precision: Waterjet Cutting Technology Advantages

Waterjet cutting is transforming modern stone landscaping with unmatched precision, versatility, and sustainability. From intricate designs to reduced material waste, this technology empowers architects, landscapers, and developers to bring creative visions to life without compromise.

5 Reasons Waterjet Cutting Is Changing the Game

Discover 5 powerful reasons why waterjet cutting is transforming stone design in Australia. From unmatched precision to eco-friendly efficiency, learn how this cutting-edge technology is shaping the future of landscaping and architecture.

The Future of Natural Stone Landscaping in Australia: Key Trends You Need to Know in 2025

Explore the top natural stone landscaping trends shaping Australia in 2025. From sustainable sourcing and minimalist design to earthy tones and waterjet precision, this guide covers the latest materials and innovations.

What is Waterjet Cutting? A Complete Guide to Modern Stone Design

Water jet cutting has been increasingly popular as a cutting process for a number of tasks throughout the years because in the world of landscaping and architectural design, precision and creativity define success.

When compared to other cutting methods, produces cleaner results, more precision, and lower costs while avoiding some of the downsides associated with other procedures, such as thermal distortion and rough finished edges. Meanwhile, traditional cutting methods often come with restrictions and limited design possibilities, wasted material, and lengthy processes.

In this article, we’ll explore five compelling reasons why waterjet cutting is the future of stone design and if water jet cutting is a viable option for your project?

What is Waterjet Cutting?

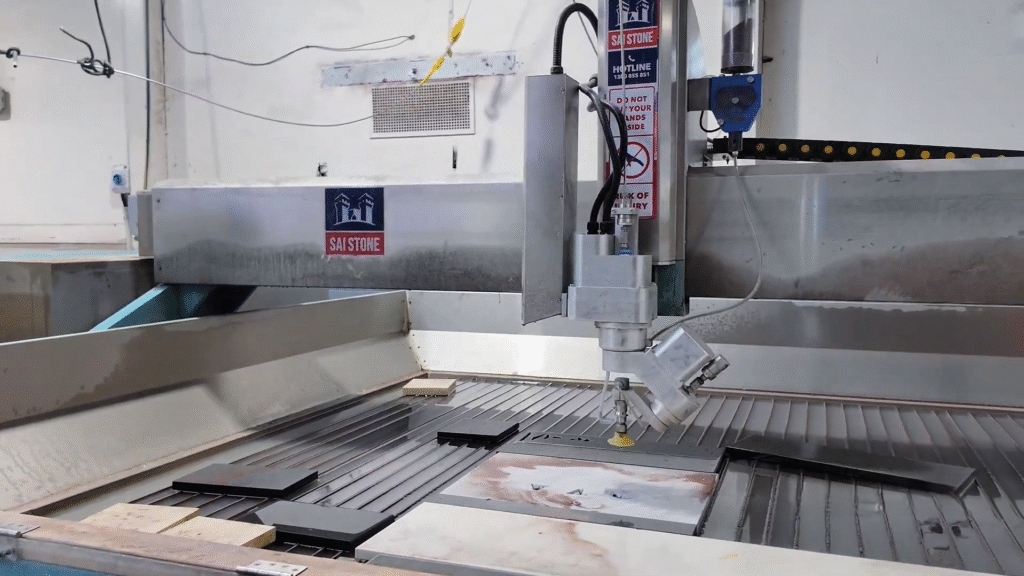

If you’re looking for waterjet cutting services in Australia right now, but you’ve got no idea what it is? Waterjet cutting is an advanced technique that uses a high-pressure stream of water, often mixed with abrasive particles, to cut through hard materials like stone, metal, and glass. Unlike traditional cutting tools that rely on heat or blades, waterjet cutting works by harnessing the sheer force of water to create smooth, precise cuts.

5 Reasons Why Waterjet Cutting is the Future of Stone Design

Unmatched Precision for Complex Designs

One of the most exciting advantages of waterjet cutting is its ability to achieve intricate, custom patterns with absolute precision. Unlike traditional saws or grinders, waterjet technology is computer-guided, which means every cut aligns perfectly with your design.

Reduced Waste and Eco-Friendly Process

The best thing about waterjet cutting services is they come with sustainability as they are very little harmful waste. This, in turn, aids in the reduction of waste disposal expenses.

Traditional cutting can produce large amounts of unusable fragments, but waterjet cutting ensures a much cleaner cut, reducing waste and maximizing material use. What makes it even more appealing? By minimizing material loss, it supports eco-conscious design approaches that many modern clients now expect.

Furthermore, they use less water than you might think because the water is recycled in a closed-loop system. The majority of waste water is clean enough to filter and dispose of down the drain. For any natural stone supplier, this efficiency means better value and improved environmental responsibility.

No Material Restrictions

There are no material restrictions with waterjet cutting, it can cut almost any material, including composites, plastics, metals, glass, stone, rock, ceramics, and rubber. It handles them all with ease, making this versatility a major reason why the method is widely adopted in both residential and commercial stone projects. Through the help of waterjet cutting, designers and builders don’t need to compromise on choice—every type of stone can be shaped into a masterpiece.

Faster Project Execution

Time is money in construction and design, and waterjet cutting significantly speeds up execution. The precision of computer-guided technology means less trial-and-error, fewer delays, and a smoother transition from concept to completion.

This advantage is especially valuable for landscaping projects in Australia, where deadlines are tight, and clients expect fast turnaround without compromising on quality. By reducing manual processing and rework, waterjet cutting keeps projects moving efficiently.

Superior Finish Without Extra Processing

Traditional cutting methods leave rough edges that require extra finishing. In contrast, waterjet cutting produces smooth, clean edges from the very first cut. Its superior finish eliminates the need for secondary polishing, saving both time and effort. For designers, homeowners, and builders, this means a seamless experience, from material selection to final installation./

Why Waterjet Cutting is the Future

Waterjet cutting represents the next step forward in stone design, combining precision, efficiency, and sustainability in ways traditional methods cannot match. Its abilities without generating heat or damaging the stone, makes it a versatile solution for both residential and commercial projects.

As demand for intricate designs, faster project timelines, and eco-friendly practices continues to grow, waterjet cutting services are becoming the preferred choice across Australia. This technology doesn’t just improve results; it sets a new standard for what’s possible in modern stonework.

Whether you’re working with marble for a luxury interior or granite for a large outdoor project, waterjet technology ensures that your vision is brought to life with accuracy, speed, and elegance.

Now that you know what waterjet cutting is and why it’s a great fit for your next metal fabrication project, search for waterjet cutting services in Australia to find a business near you. Choose SAI Stone, the natural stone supplier Australians trust for precision and durability.

Since 2005, SAI Stone has been crafting durable, beautiful, and sustainable stone designs. Today, they also offer advanced waterjet cutting services across Australia, bringing precision and innovation to every project.